The Mono Manufacture in Mettmann, North Rhine-Westphalia

This is the place where design history has been written since 1959. Production, grinding shop, warehouse, assembly, shipping as well as administration and sales offices are located on approximately 2000 square meters. Some things have changed here, but much has remained the same. Large parts of inventory management, sales and communication have become digitalized, LED lights illuminate the production hall and employees come to work on e-bikes. At the same time, traditional manufacturing methods are being adhered to with stubborn conviction in the belief that craftsmanship, the human eye and high-quality materials really do make a difference.

1/

6

The Mono manufactory in Mettmann. 28 employees take care of continuous design history made by hand.

The distances in the manufactory are short. On 2224 square meters are production, grinding shop, storage, assembly, shipping, as well as administration and sales office.

Family business in the 6th generation. Wilhelm Seibel sen. took over the company in 1983 from his uncle Herbert Seibel. Wilhelm Seibel has been managing the company since 2001. His sons Johannes (l) and Matthias (r) are responsible for marketing and production.

The most important tools remain eyes, feeling and experience. For six generations, the know-how has been passed on at the manufactory.

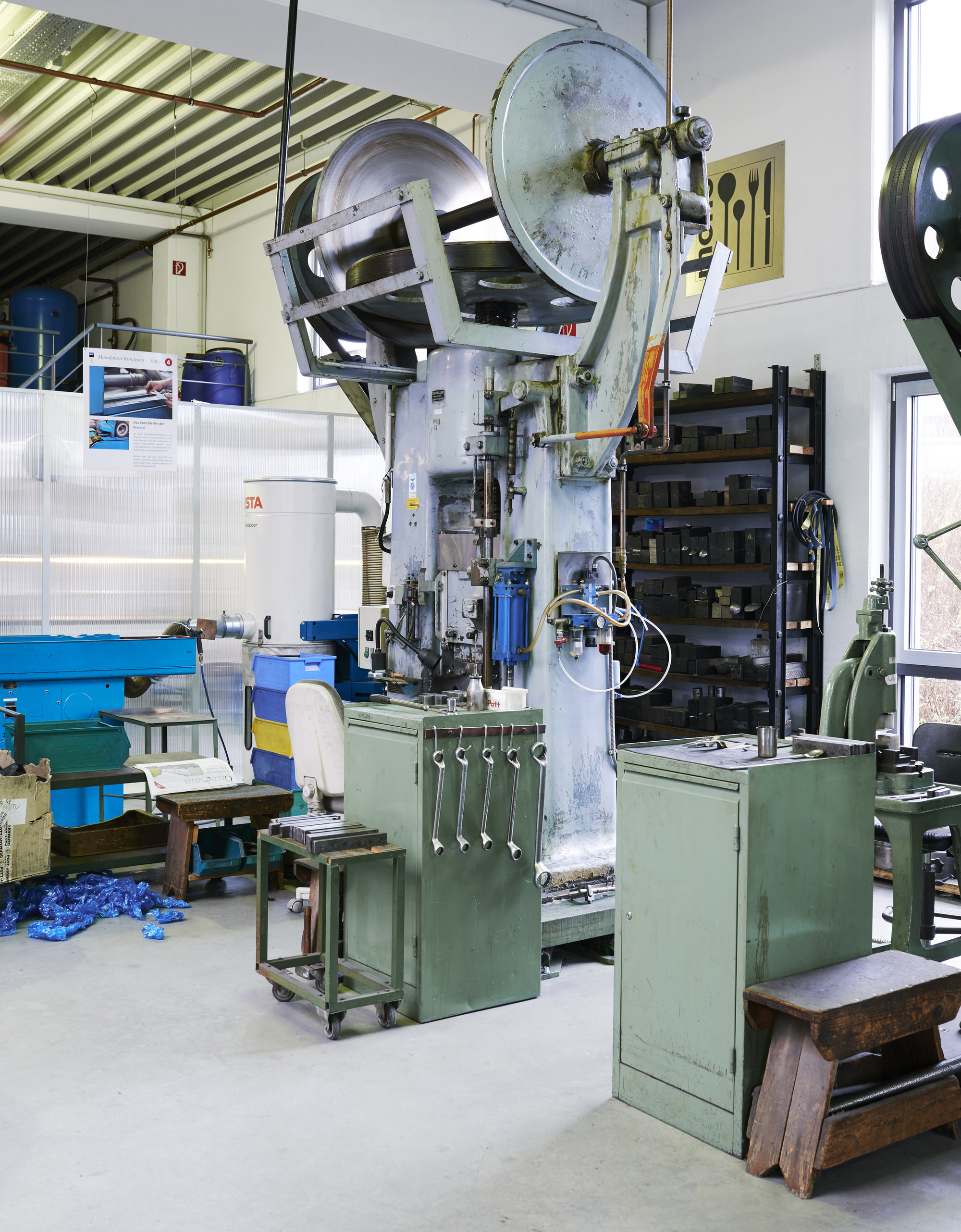

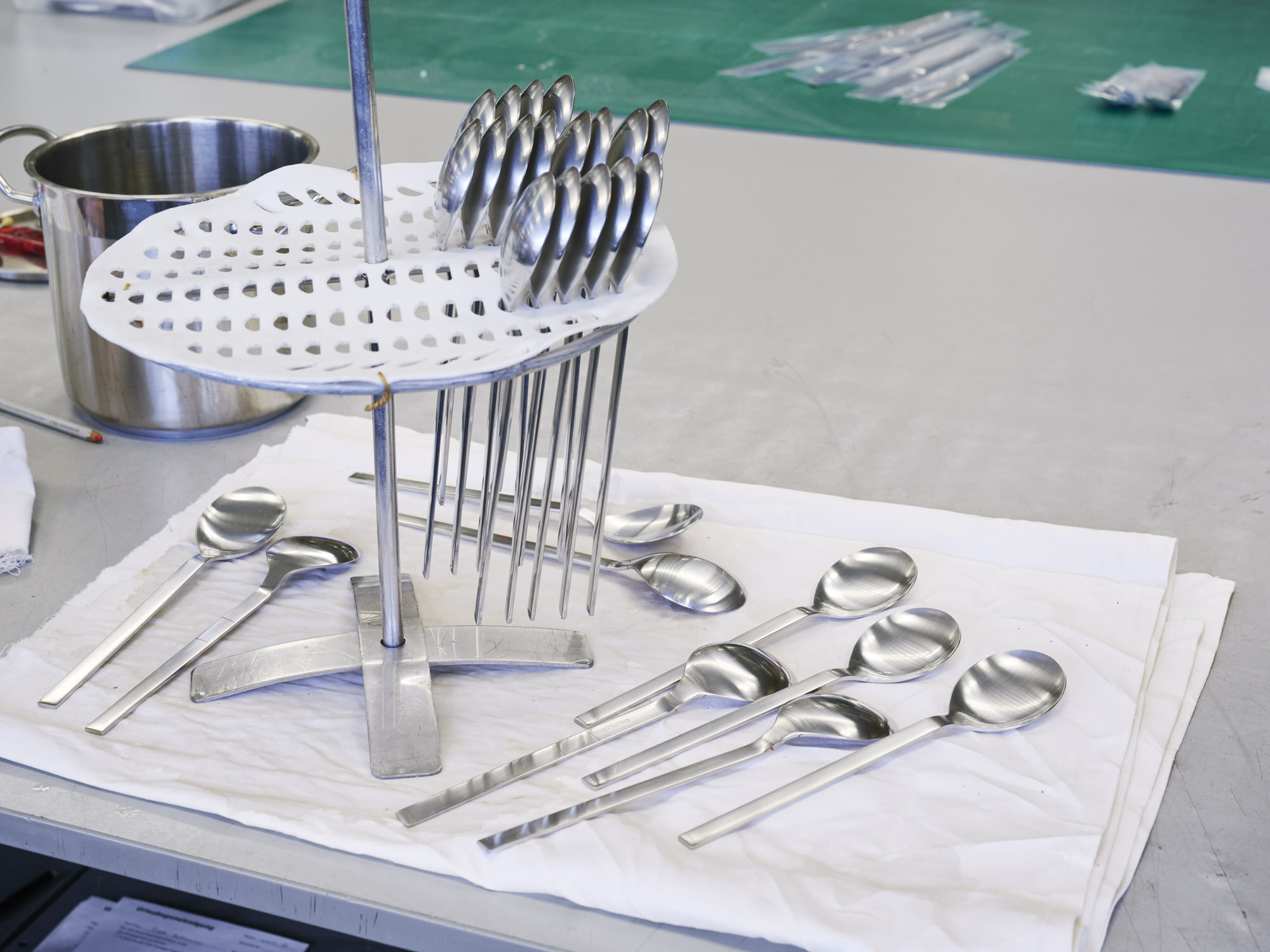

The capital of the manufactory are the various tools that are used for the production of the Mono flatware classics.

The heart of a flatware manufactory remains the grinding shop.

This screw press deforms a piece of flatware into the third dimension with up to 280 tons per cm2.

Quality does not have to be new, this applies to design and machine. The well maintained machinery are the basis for a perfect Mono product.

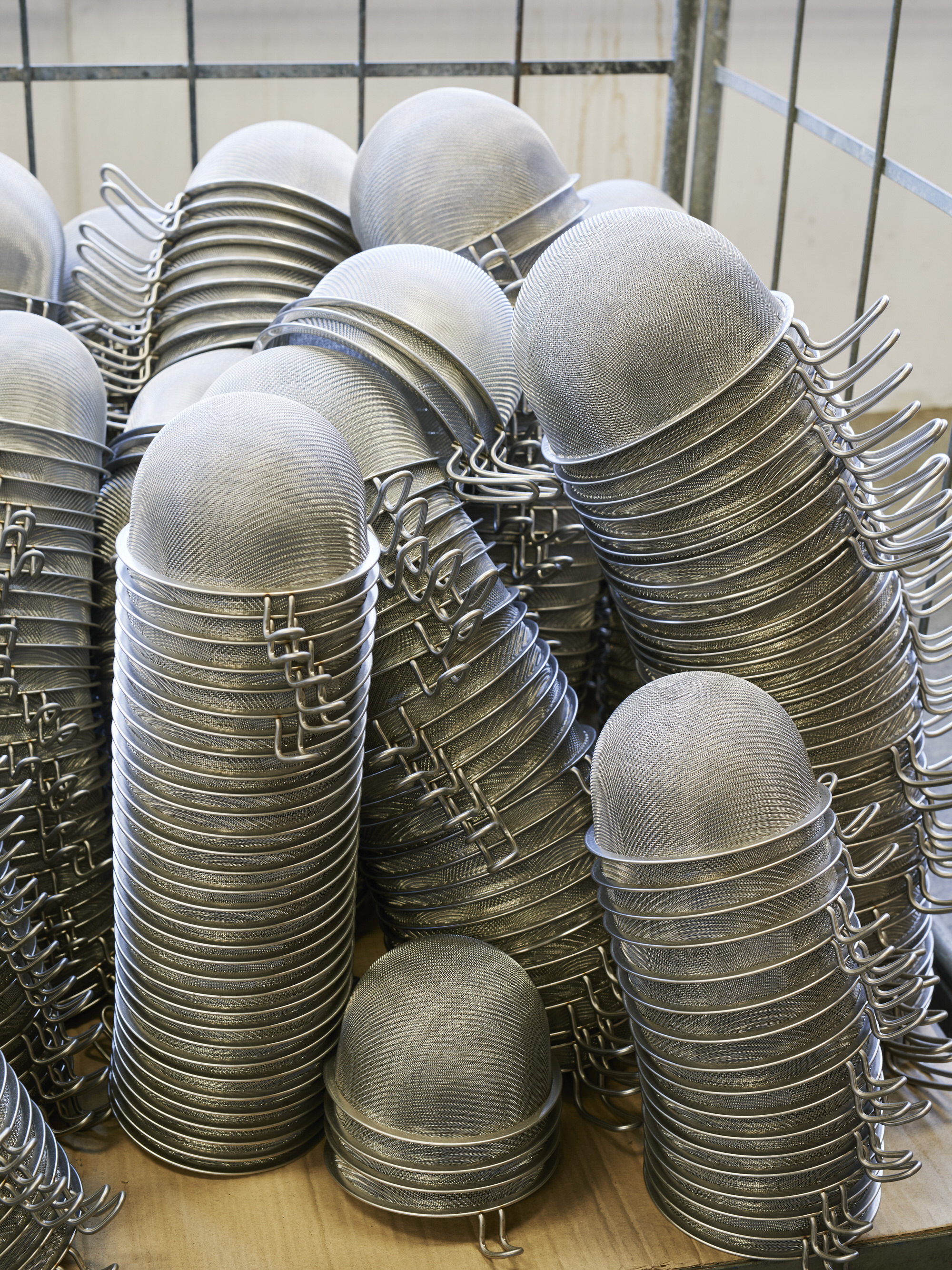

The own production share at Mono is very high at 85%. For delivered parts Mono attaches importance to quality and regionality. The tea strainers are e.g. from the company Dorstener Drahtwerke 60 kilometers from the Mono manufactory.

Every year, about 2,000 spoons get the finishing touches in the Mono manufactory. A typical lot size in serial manufacturing work is 50 pieces.

Quality control with keen eyes. Only when perfection is achieved does a Mono product leave the manufactory.

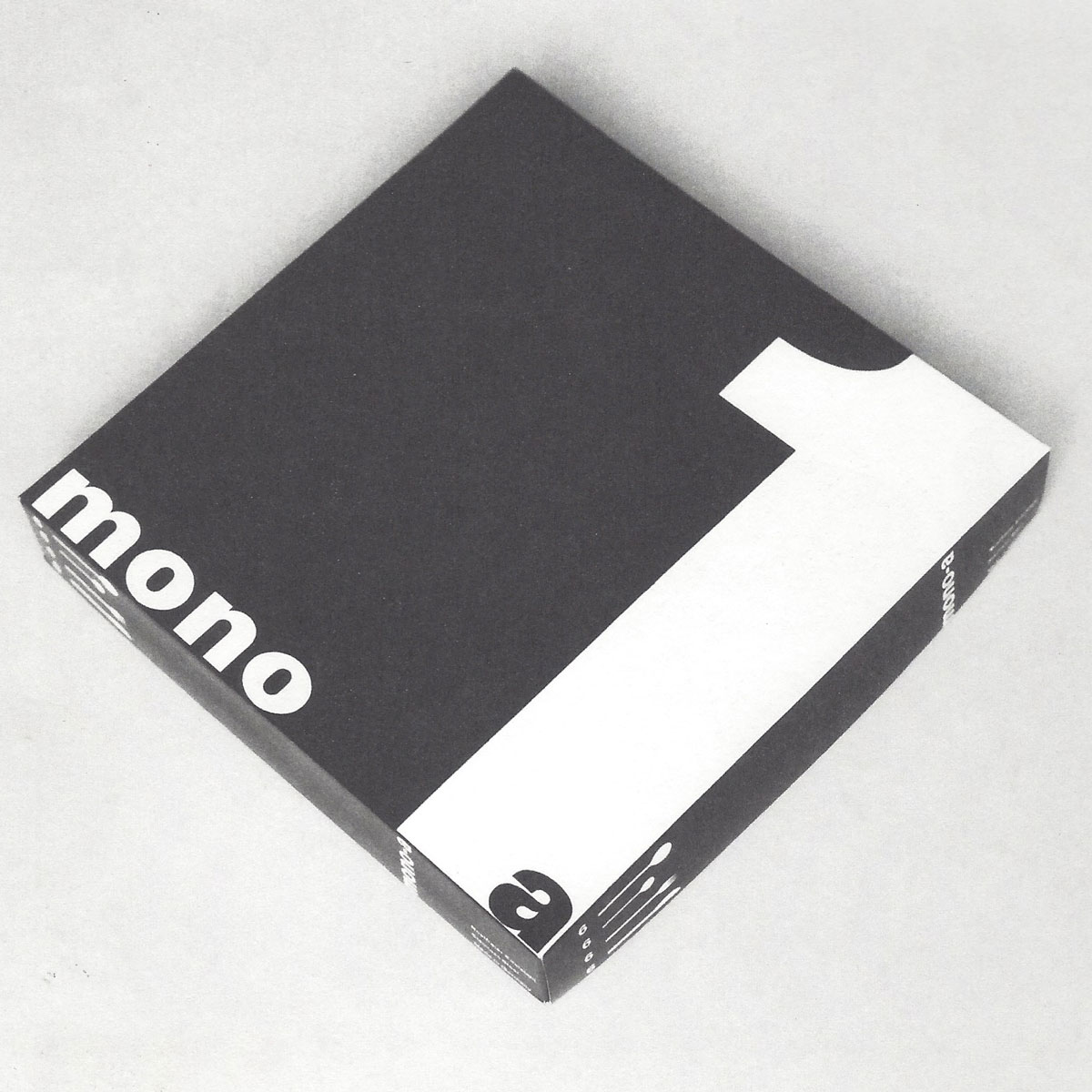

From Mettmann to the World. After final quality control and safely packed, the Mono products leave the manufactory.

Discover next