Made in Germany since 1959

With the development of Mono A flatware in 1959, the foundation for the flatware program and the Mono Design DNA was laid. In addition to Peter Raacke's classics (A, E, T, Oval, Petit), Mono Zeug (the Neanderthal flatware by Michael Schneider, 1995) and the Mono Ring re-edition (collaboration between Peter Raacke and Mark Braun, 2018) belong to the Mono flatware portfolio. All Mono flatware are mostly made by hand in the manufactory in Mettmann, Germany. Some 30 steps are used until the final flatware product is finished. The product is under constant evaluation, and only then and when the final touch is made, and perfection is reached, is the product released from the manufactory.

1/

4

1/

5

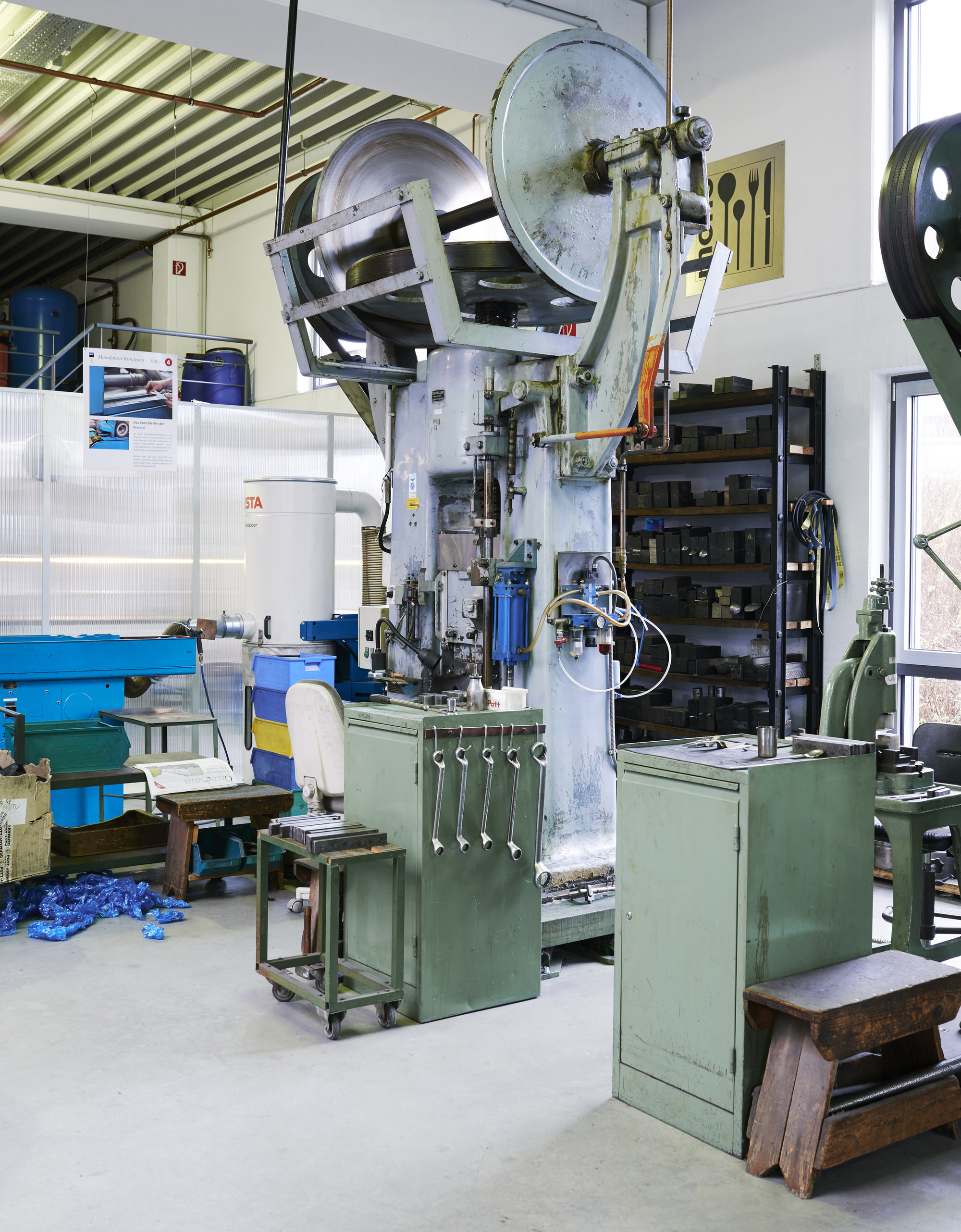

The Mono manufactory in Mettmann. 28 employees take care of continuous design history made by hand.

The distances in the manufactory are short. On 2224 square meters are production, grinding shop, storage, assembly, shipping, as well as administration and sales office.

Family business in the 6th generation. Wilhelm Seibel sen. took over the company in 1983 from his uncle Herbert Seibel. Wilhelm Seibel has been managing the company since 2001. His sons Johannes (l) and Matthias (r) are responsible for marketing and production.

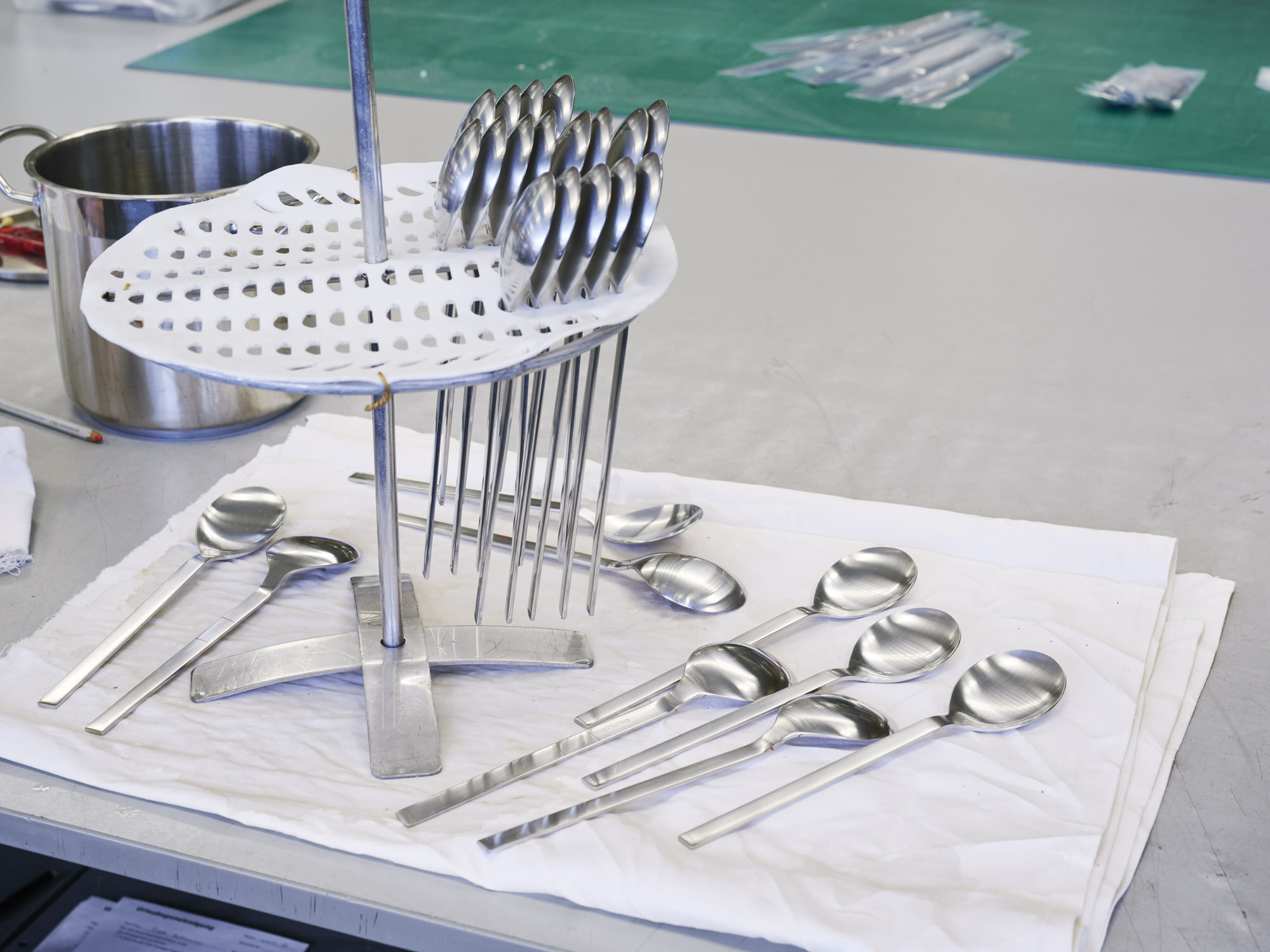

The most important tools remain eyes, feeling and experience. For six generations, the know-how has been passed on at the manufactory.

The capital of the manufactory are the various tools that are used for the production of the Mono flatware classics.

The heart of a flatware manufactory remains the grinding shop.

This screw press deforms a piece of flatware into the third dimension with up to 280 tons per cm2.

Quality does not have to be new, this applies to design and machine. The well maintained machinery are the basis for a perfect Mono product.

Every year, about 2,000 spoons get the finishing touches in the Mono manufactory. A typical lot size in serial manufacturing work is 50 pieces.

Quality control with keen eyes. Only when perfection is achieved does a Mono product leave the manufactory.